Cold Milling Machine Market: Global Growth, Technological Advancements, and Future Outlook 2024-2034

Cold Milling Machine Market: Global Growth, Technological Advancements, and Future Outlook 2024-2034

The Cold Milling Machine Market is emerging as one of the most dynamic segments within the construction and road infrastructure industry. Cold milling machines, also referred to as cold planers, play a pivotal role in road construction, rehabilitation, and maintenance by enabling precise removal of asphalt and concrete surfaces without the drawbacks of conventional hot milling. Their increasing adoption worldwide is fueled by infrastructural development, technological advancements, sustainability concerns, and government initiatives targeting road modernization.

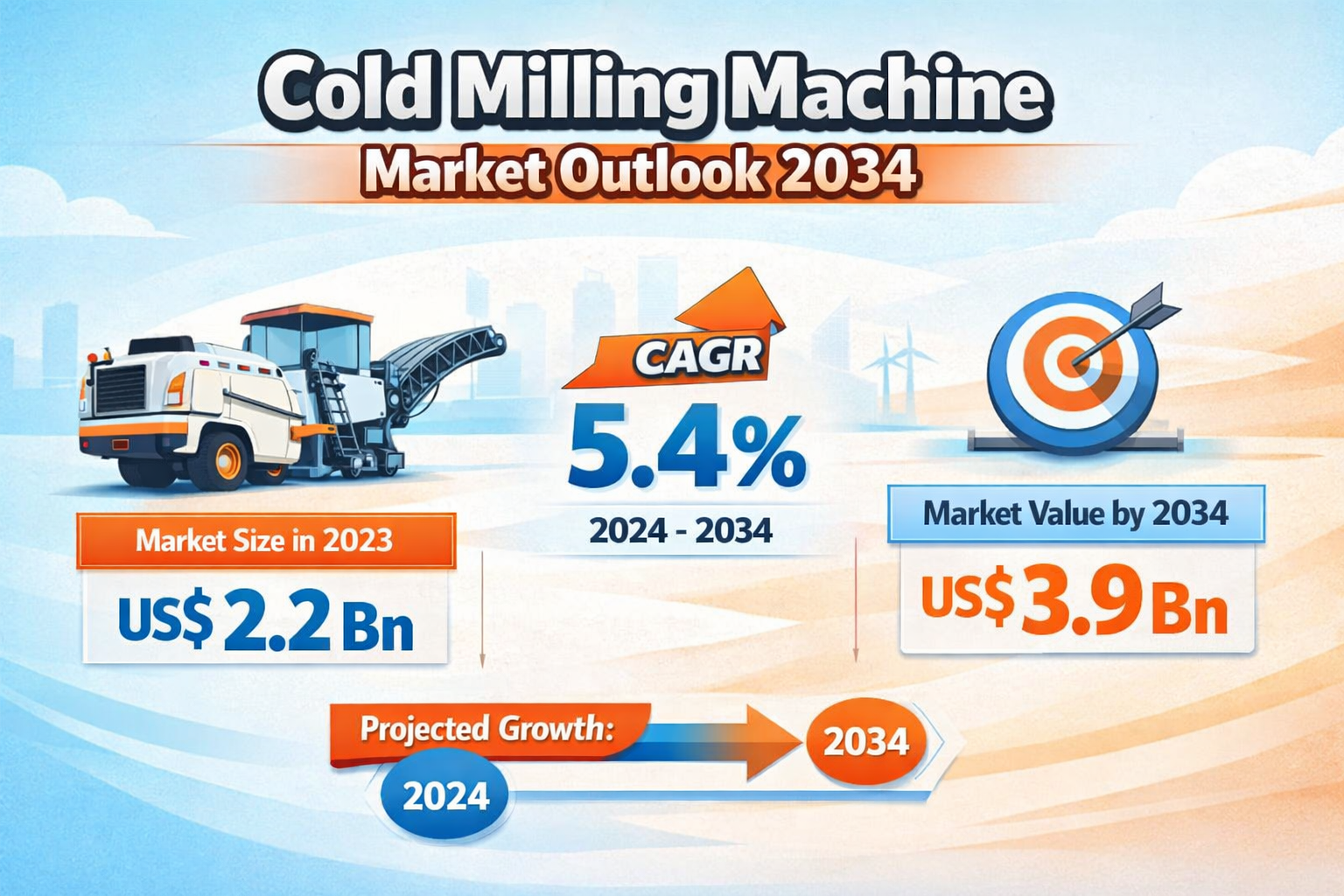

Market Overview and Size

In 2023, the global cold milling machine industry was valued at US$ 2.2 billion. Analysts estimate that the market will grow at a CAGR of 5.4% over the forecast period from 2024 to 2034, reaching approximately US$ 3.9 billion by 2034. This steady growth reflects the rising demand for efficient road construction and rehabilitation equipment across developed and emerging economies.

Cold milling machines offer precise material removal, minimal waste generation, and on-site recycling capabilities. Unlike traditional hot milling, cold milling does not overheat materials, preserving their integrity and enabling eco-friendly practices. As infrastructure networks expand and age, the necessity for effective resurfacing tools ensures a consistent demand for cold milling technology.

Key Drivers of the Cold Milling Machine Market

1. Increasing Infrastructure Development and Road Construction Projects

Infrastructure development remains a primary driver for cold milling machine adoption. Governments worldwide are heavily investing in the construction and modernization of road networks to boost economic growth and connectivity. For instance:

-

India: Through the National Infrastructure Pipeline (NIP), the Indian government aims to invest over US$ 1.4 trillion in infrastructure before 2025, creating significant demand for cold milling machines.

-

United States: The Infrastructure Investment and Jobs Act allocates US$ 1.2 trillion for roads, highways, and transportation, underscoring a nationwide commitment to upgrading infrastructure.

-

Global Perspective: According to the Global Infrastructure Hub, total investment in global infrastructure is projected to reach US$ 94 trillion by 2040, with road construction forming a major segment.

Moreover, aging roads in developed countries require frequent maintenance and rehabilitation. The American Society of Civil Engineers (ASCE) assigned an all-time low grade of C- to U.S. infrastructure, highlighting the urgency for repair work. Cold milling machines, being cost-effective and precise, are essential tools for such initiatives.

2. Technological Advancements and Innovation

Modern cold milling machines incorporate advanced technologies to improve efficiency, reduce operating costs, and enhance performance. Notable innovations include:

-

Automation: Leading manufacturers such as Wirtgen Group have integrated automation systems into their machines, reducing operator workload while improving milling precision. Automated control systems allow for consistent milling depth and better surface quality.

-

GPS Integration: Companies like Volvo Construction Equipment offer GPS-enabled cold milling machines, ensuring high accuracy in road rehabilitation projects, reducing material waste, and enhancing project efficiency.

-

Fuel Efficiency and Emission Standards: Caterpillar has introduced engines meeting Tier 4 emission standards, appealing to environmentally-conscious buyers by reducing fuel consumption and minimizing environmental impact.

These technological advancements not only improve operational efficiency but also attract contractors looking for modern, environmentally-friendly solutions.

3. Focus on Sustainability and Recycling Practices

Environmental concerns and sustainability regulations are reshaping the construction equipment market. Cold milling machines are at the forefront of this transformation due to their inherent ability to recycle materials on-site:

-

Recycling of Asphalt and Concrete: Milled material can be reused in new asphalt or concrete mixtures, reducing the need for virgin raw materials. This practice aligns with circular economy principles, minimizing waste and conserving natural resources.

-

Compliance with Regulations: Governments worldwide are increasingly mandating sustainable construction practices, emphasizing reduced carbon emissions and efficient material use. European Union regulations, including the Green Deal, further promote eco-friendly construction technologies.

-

Cost Efficiency: By recycling materials, contractors can reduce costs associated with material procurement, transportation, and disposal, making cold milling a financially attractive solution.

The combination of environmental sustainability and operational efficiency positions cold milling machines as essential tools for modern infrastructure projects.

Market Segmentation

The cold milling machine market is segmented based on product type, size, engine power, and application.

By Product Type

-

Drum-Type Cold Milling Machine: Suitable for high-precision milling on highways and major roads.

-

Crawler-Type Cold Milling Machine: Offers enhanced mobility and stability for uneven terrains.

-

Wheel-Type Cold Milling Machine: Designed for specialized applications requiring faster movement and minimal surface disruption.

By Size

-

Small: Ideal for minor projects, local roads, and repair works.

-

Compact/Medium: Balances power and maneuverability for urban and regional roads.

-

Large: Suitable for highways, airports, and large-scale infrastructure projects.

By Engine Power

-

Less than 155 kW

-

155–300 kW

-

Above 300 kW

By Application

-

Asphalt Pavement: Resurfacing and repair of roads with asphalt layers.

-

Concrete Pavement: Milling of concrete surfaces for maintenance and reconstruction.

-

Others: Removing pavement markings or specialized resurfacing tasks.

These segments ensure that cold milling machines cater to a wide range of project requirements, from small municipal roads to extensive highways and expressways.

Regional Outlook

Asia Pacific

The Asia Pacific region dominates the cold milling machine market, driven by rapid urbanization, government investment, and large-scale road construction projects. Countries like China, India, and Japan are central to this growth:

-

China: The Belt and Road Initiative (BRI) encompasses thousands of road projects across Asia, boosting demand for milling equipment.

-

India: Significant funding through the NIP ensures enhanced connectivity and modernized transport networks.

-

Infrastructure Funding: The Asian Development Bank (ADB) estimates annual infrastructure investment in developing Asia at US$ 1.7 trillion, with a significant focus on transportation.

North America and Europe

Steady growth in North America and Europe is fueled by infrastructure rehabilitation projects, technological adoption, and compliance with environmental regulations. Governments in these regions emphasize sustainable practices and maintenance of aging road networks.

Middle East, Africa, and South America

These regions are witnessing emerging growth due to increasing government spending on road infrastructure, urbanization, and industrial expansion. Cold milling machines are increasingly adopted to modernize transportation networks efficiently.

Competitive Landscape

The cold milling machine market is highly competitive, with key players investing in product development, technological innovations, and regional expansion. Leading companies include:

-

Astec Industries, Inc. (Roadtec)

-

Bomag GmbH

-

Caterpillar Inc.

-

CMI Roadbuilding Limited

-

Fayat Group

-

Jiangsu Huatong Power Heavy Industry Co Ltd.

-

Liugong Machinery Co Ltd.

-

Sakai Heavy Industries, Ltd.

-

SANY GROUP

-

WIRTGEN

Recent Developments:

-

Sany Group (2024): Launched truck-mounted concrete pumps in Athens and Thessaloniki, expanding product offerings.

-

Caterpillar (2024): Introduced VisionLink® Productivity, a digital solution for PM600 and PM800 series cold planers to optimize operational efficiency and improve project monitoring through data analytics.

The competitive environment emphasizes innovation, automation, fuel efficiency, and sustainability, pushing manufacturers to develop advanced solutions that meet evolving market needs.

Future Outlook and Opportunities

The outlook for the cold milling machine market is highly positive, with several opportunities driving long-term growth:

-

Infrastructure Investment: Government spending on road networks, bridges, and airports globally will continue to fuel demand.

-

Technological Integration: AI, IoT, and GPS-enabled machines will enhance precision and efficiency, attracting modern construction firms.

-

Sustainability Initiatives: The growing emphasis on circular economy principles and environmentally-conscious practices ensures adoption of eco-friendly cold milling machines.

-

Emerging Economies: Rapid urbanization and industrialization in Asia, South America, and Africa create new markets for heavy construction equipment.

-

Public-Private Partnerships (PPPs): Collaborative infrastructure projects provide opportunities for equipment leasing, rentals, and new product deployment.

Despite the high initial investment and need for skilled operators, cold milling machines are increasingly indispensable in modern road construction, offering efficiency, sustainability, and long-term cost benefits.

Analysts’ Viewpoint

Experts believe the cold milling machine market is poised for sustained growth due to the convergence of infrastructure investment, technological innovation, and environmental sustainability. As governments and private contractors increasingly prioritize precision, cost-efficiency, and eco-friendly practices, cold milling machines are set to play a central role in global road construction and rehabilitation projects.

Conclusion

The Cold Milling Machine Market is on a steady growth trajectory, driven by global infrastructure initiatives, technological advancements, and sustainability-focused construction practices. With ongoing innovation, recycling capabilities, and increasing adoption in emerging economies, the market is set to achieve substantial expansion over the next decade.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness